Jain Mill Store Manufactures, Supplier ,Distributes and Exports PTFE gasket for industrial applications. We are specialized in custom PTFE Gaskets that are manufactured to meet the specific requirements for each job.

PTFE Gasket is also known as Teflon is one of the materials made up of fluorocarbon polymerwhich. The sheets are hydrophobic which makes them highly Aqua Resistant that is why these are also used in containers and Pipe works.

PTFE can be modified for gasket used material with strong chemical resistance properties. This unique structure of the Gaskettends to maximize the performanceStability and predictability while minimizing creep and cold flow.

Basic Characteristics of PTFE Gasket

The operating temperature of PTFE Gasket with no filters ranges between -75⁰C to +260⁰C. It is finest non-stick material with friction comparable to wet ice. It is completely resistant to attack by majority of chemicals with the exception of molten alkaline metals and few fluorine compounds.

PTFE Gaskets can have fillers added blending with base PTFE Compound. The fillers increase creep hardness resistant, chemical resistance, and fulfil requirements for selected industries.

- PTFE gaskets are one of the best gaskets known; they can be insulated to 500 volts per mil to suit the needs of the machinery. In Electrical Industries these are frequently used in wire and cable wrap, and to separate conductive surfaces in capacitors.

- In Chemical Industries PTFE is the best choice for gasketspump interiors, vessel linings,spacers, seals, dip tubes and drilling components.

- In Petro- Chemical Industries these Gaskets are usedfor process machinery and Equipment that are resistant to Mordant fluids, temperature extremes, and surface wear.

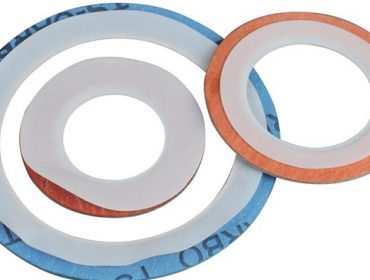

- Virgin PTFE

Virgin PTFE gaskets are produced directly from refined material

- Filled PTFE

Filled PTFE gaskets are made from Virgin PTFE material with adding some other elements to improve its Blockade properties

- Expanded PTFE

Expanded PTFE gaskets are produced through Virgin PTFE being expanded in a manner that creates uniform tension strength across the material.