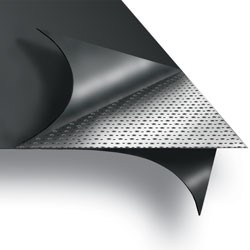

Pure Graphite Sheet / Graphite Roll

Flexible Graphite Sheet Twill is made with pure mineral graphite. It is 99% carbon purity graphite sheet. High carbon purity flexible graphite sheet, improved chemical resistance, provides better thermal conductivity and better sealing. Gasket as the material is produced as if graphite or doped graphite sheet layer and is widely used in fluid sealing area. This material as solid lubricants for metal cutting and forming processes in industrial furnaces and other heat treatment can be used as heat insulation material looms.

We hold expertise in offering supreme quality Flexible Graphite Sheet Roll to our esteemed customers. Owing to their good thermal conductivity, these sheets and rolls are used for manufacturing of flange gasket. With a well-equipped distribution network, we deliver these sheets and rolls within promised time frame at the customers’ doorstep withour any compromise on quality.

- Smooth finish

- Ability to withstand extreme temperature

- Long functional life

- High-carbon ratio, minimum % 99

- Rubber contains no binder and no amount of asbestos. (100% asbestos free)

- Chemically, it is resistant to oxidation and corrosion

|

TECHNICAL SPECIFICATIONS |

APPLICATION AREA |

||

|

Value |

Graphite Sheet |

Graphite Roll |

This product thermal stability, very low and high temperature suitability, has excellent properties such as resistance to corrosion. Sealing rings shaped in a mold and used a lot in making various gaskets. |

|

Intensity |

0.7 – 1.2 g/m3 |

0.7 – 1.1 g/m3 |

|

|

Length |

≤ 1000 mm |

30-100 m |

|

|

Width |

≤ 1000 mm |

≤ 1000 mm |

|

|

Thick |

0.5 - 5 mm |

0.2 - 0.8 |

|

|

|

Clas I |

Clas I |

|

|

Density tolerance, gr/cm3 |

± 0.05 |

± 0.06 |

|

|

Kalınlık toleransı, mm |

± 0.03 |

± 0.04 |

|

|

Carbon ratio, % |

99 |

98 |

|

|

Tensile strength, Mpa |

≥ 4.5 |

≥ 4.5 |

|

|

Compressibility, % |

> 40 |

> 40 |

|

|

Rate assumes its original shape, % |

> 10 |

> 10 |

|

|

Sulfur content, PPm |

< 700 |

< 1000 |

|

|

The ratio of chlorine, PPm |

< 35 |

< 50 |

|

|

Stress-free rate, % |

10 |

10 |

|

|

Mass loss at high temperature, % |

< 0.5 |

< 1 |

|

|

Pressure |

30 Kgf/cm2 |

||

|

PH |

0 - 14 |

||

|

Operating temperature |

Oxidizing / non-environment:-240 ~ 600 0C / -240 ~ 750 0C |

||