Asbestos Cloth Definition

It is made of asbestos wires by means of vertical and horizontal knitting. It is a insulation material used in heat-preservation of pipes. In addition, it can also be made into gloves, working garments and rubber liner materials. If necessary, the asbestos cloth can be offered to clamp metal threads.

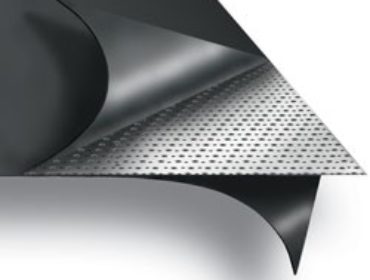

- Asbestos Rubber Sheets

- Oil Resistance Asbestos Rubber Sheets

- Acid Resistance Asbestos Rubber Sheets

- Non-Asbestos Rubber Sheet

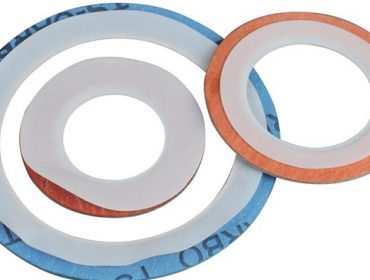

- Asbestos Rubber Gasket

Asbestos Cloth Description

Asbestos has been used for more than 2,000 years. It was named by the Ancient Greeks, its name meaning “inextinguishable”. Asbestos cloth woven from asbestos yarns used in a number of diversified application in a variety of textures, thicknesses and weights to suit these applications. Further, they possess excellent fire, rot and vermin proof qualities. Also known as anthrophylite and actinolite cloth. The Asbestos cloth is used manufacturing fire blankets, belts for conveying heated materials through ovens and in dryers, wrapping for sheet glass, shields to protect workmen from fire and all types of safety clothing etc. Moreover, our products can be custom made as per specifications detailed by clients.

Backed by a team of diligent experts, we manufacture and export high quality asbestos cloth used in the textile industry. It is a type of cloth to form pliable mineral textile with high tensile strength and high resistance to heat, flame, chemicals, and weather. We fabricate this type of cloth using qualitative fine quality longer spinning fiber of asbestos which makes our product endurance better.

We offer 1.5mm cloth in 3 grades e. g. 750gm,850mm to 900gm , 1.05kg GSM. This primarily is used in making gloves similar to S-20 or AMC-41 hand gloves. Secondly in making asbestos sheets, asbestos circles, aprons and elsewhere depending on various usage. Its available in a meter width in 50meters length.

Asbestos Cloth Technical Specification

| Size MM | Grades | GSM | Temp C |

| 1.5 | Semi | 850 | 300 |

| --- | Semi | 1000 | 300 |

| --- | Commercial | 450-550 | 200 |

| 2.0 | Semi | 1100 | 300 |

| 3.0 | Semi | 1600 | 300 |

| --- | Commercial | 1500 | Appx 200 |

| 6.0 | Semi | 1800 | 300 |

| --- | Commercial | 1650 | Appx 200 |

| 1.5 Special | Semi | 750 | 300 |

Product wise application search strings

Asbestos cloth are used for boilers, pipelines and ancillary equipments in power plants, factories, buildings, steel plants, pharmaceutical companies, heat treating plants and ships.

For the manufacture of fire-resistant gloves, suits and other clothing for firefighting; also for heat-resistant gloves, aprons, etc. for use in glass works, foundries, chemical works, welding shops, plastic moulding shops, etc. For use as safety-curtains in theaters, ships and aircraft and wherever a fire barrier is required. For the manufacture of fire blankets for use in ships, schools, institutions, cinema projection rooms, kitchens, garages etc., and wherever there may be a need for clean and effective means of smothering during small outbreaks of fire.

Asbestos cloth, when proofed with rubber, is an excellent jointing medium. It can be folded into tapes and rings, and cut into gaskets for the sealing of pipe flange joints and boiler joints. It is also lubricated and shaped into proofed asbestos cloth packings.

For the diaphragms of electrolytic cells, in Vanaspati units etc.

As a filler in high-strength, heat-resistant laminates for electrical applications.

As a filtration medium for various liquids.

History of Asbestos Cloth

- Places Used: Oil refineries, power plants, aluminum plants, steel plants, foundries, homes, offices

- Toxicity: Medium

- Asbestos Use Banned: No

- Textile Cloth Friable: Yes

- Textile Garments Friable: No

While the use of asbestos in cloth can be traced back as far as 2500 B.C., it wasn’t until the late 1800s that it was commercially produced in the United States. One of the first companies to produce asbestos textiles was Johns Manville, which began manufacturing the cloth in 1884. As demand for the material rose — and because asbestos was spun in a similar method to cotton — several textile mills that were built to process cotton were converted to asbestos textile factories in the early 1900s.

Asbestos fibers of different grades were mixed in a fiber blender according to specifications of the intended product. The fibers are then combed into a fiber mat. The mat is pressed and layered into an arrangement of fiber mats called a lap. Thin ribbons, called roving, are made from the lap. At this stage, other fibers like cotton or rayon can be added. The roving is further spun and twisted to form yarn. Yarn can then produce thread. Thread can be used to make fabric for garments, rope, wicking or even tape.

In the United States, the Carolinas were particularly instrumental in the industry. There were large deposits of naturally occurring asbestos in both states, and textile mills were established in former cotton mills near the mines.